NANOTECH-DISTRIBUTIONS

NANOTECH-DISTRIBUTIONS seeks to revolutionize the chemical market by replacing Teflon and fluorocarbon-based products with green silicon dioxide (SiO2) -based nanotechnology.

Our products of German origin meet the optimal quality standards for industrial use.

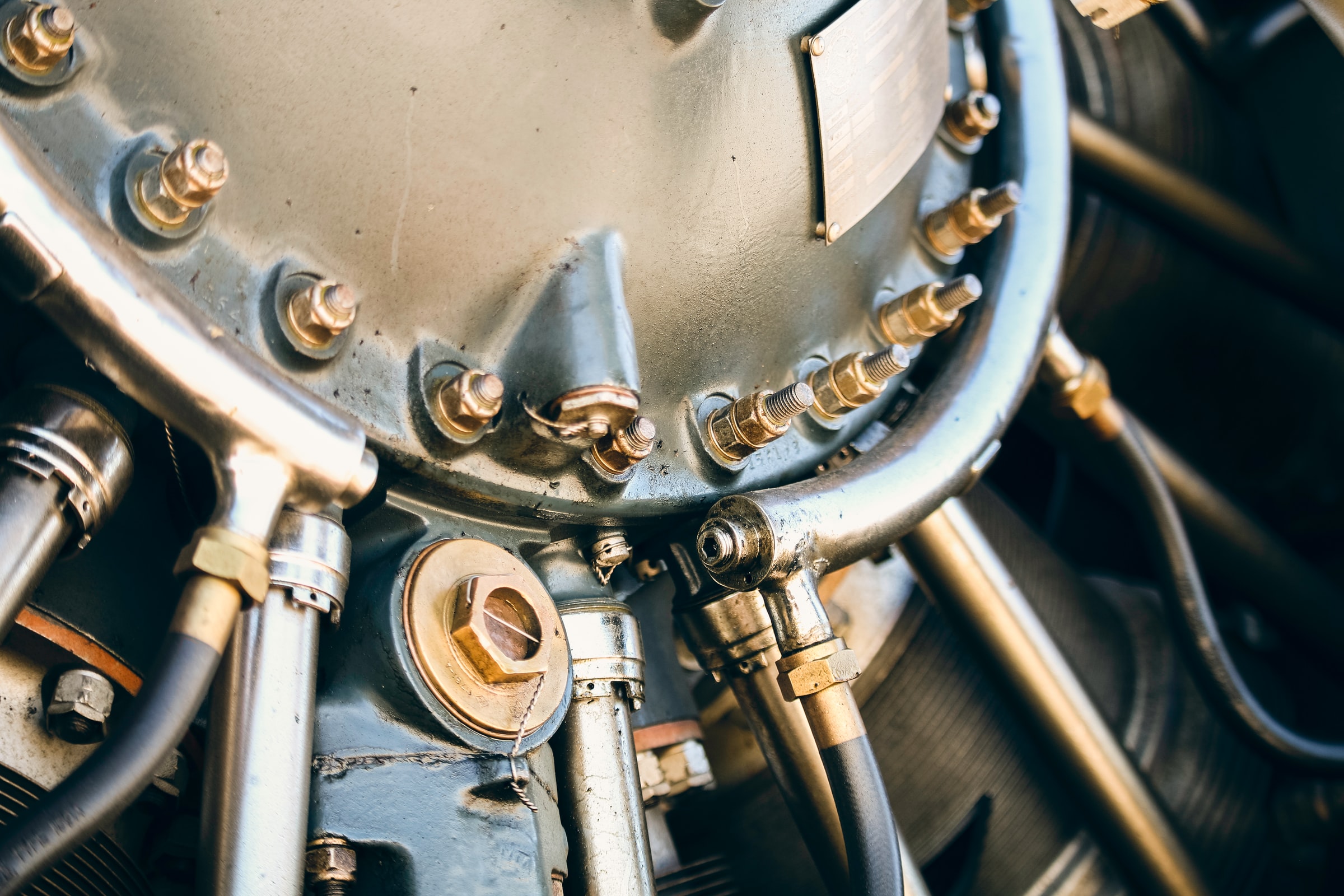

Xeramic

Silicon-based protective ceramic nanocoating that changes surface energy, resulting in strong non-stick properties for industrial surfaces.

- Extends the useful and productive life of the mold surface.

- Greener and cleaner processes.

- Optimize production times.

- Avoid constant maintenance.

- Significant reduction in the use of release agents.

PRODUCT CHARACTERISTICS

Chemical formulated of water-based organic acids focused on inhibiting corrosion by phosphatizing process, it presents an Eco friendly base.

- Anticorrosive

- Eliminates Saline Agents

- Protection Properties

- Flexibility and Adaptability

- Not toxic

- Create Anchor Profile

- Penetrates Porosity

- Degreaser

- Precipitation Cleaning

Identification of the problem

Competitive advantages

- It is not toxic with flora and fauna.

- Creates an invisible anticorrosive protection, up to 5 days.

- It is neutralized in contact with fresh, salty or saline water.

- It can be reused until its color changes from colorless to brown.

- It can help clean welds or steel bodies in poor condition.

- Being a liquid, it can penetrate the substrate better, making cleaning more detailed.

- It easily replaces traditional metal corrosion removal methods such as sandblast, hydroblast, abrasive chemicals, among others.

Uses and applications

- Focused on the neutralization of rust in carbon steel and stainless steel such as:

- Elimination of carbide precipitates in welding on stainless steel.

- Degreasing of carbon and stainless steel parts, equipment or bodies.

- Elimination of saline agents on wood or concrete.

- Corrosion of sheet or plate bodies.

- Welds or unions in carbon steel.

Our ceramic tiles are made up of different types of precursors: organic pre-ceramic and quartz.

Before application

After the application

Corrective Solutions

A CRYOGENIC cleaning (high pressure dry ice in small particles) is performed as a suggested method for optimal results. Or the use of some other cleaning method that guarantees surface decontamination.

Preventive Solutions

The product is applied on the surface in a uniform way, anticipating the most critical contact points between the pieces and the casting material.