Zinnox & OXI-CLEAN

They will keep the surfaces armored, transforming them into anticorrosive with a durability of up to 3 years.

They are the best coatings to prevent all forms of corrosion that invade industrial processes, electrical systems and materials exposed to the elements.

Zinoxx

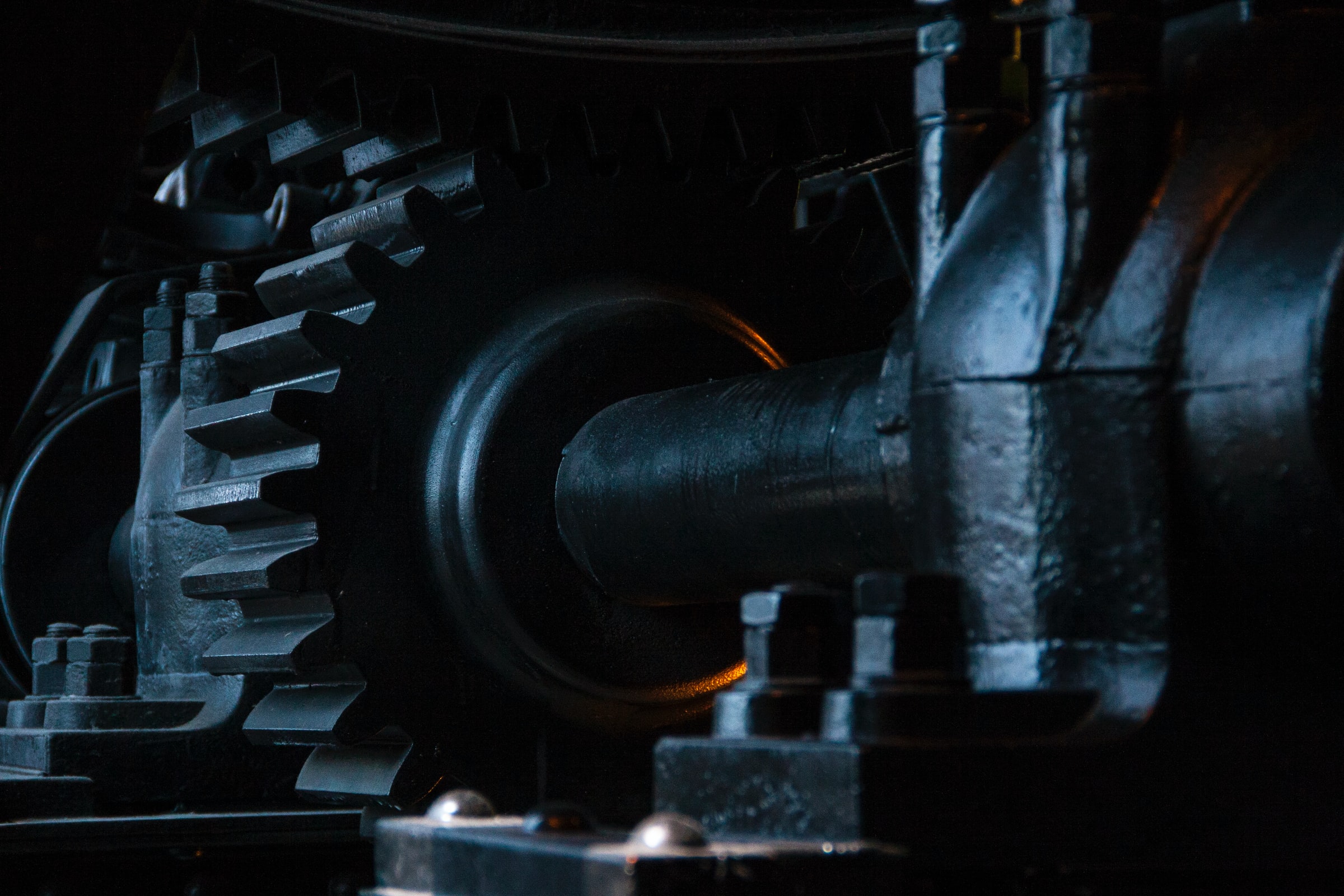

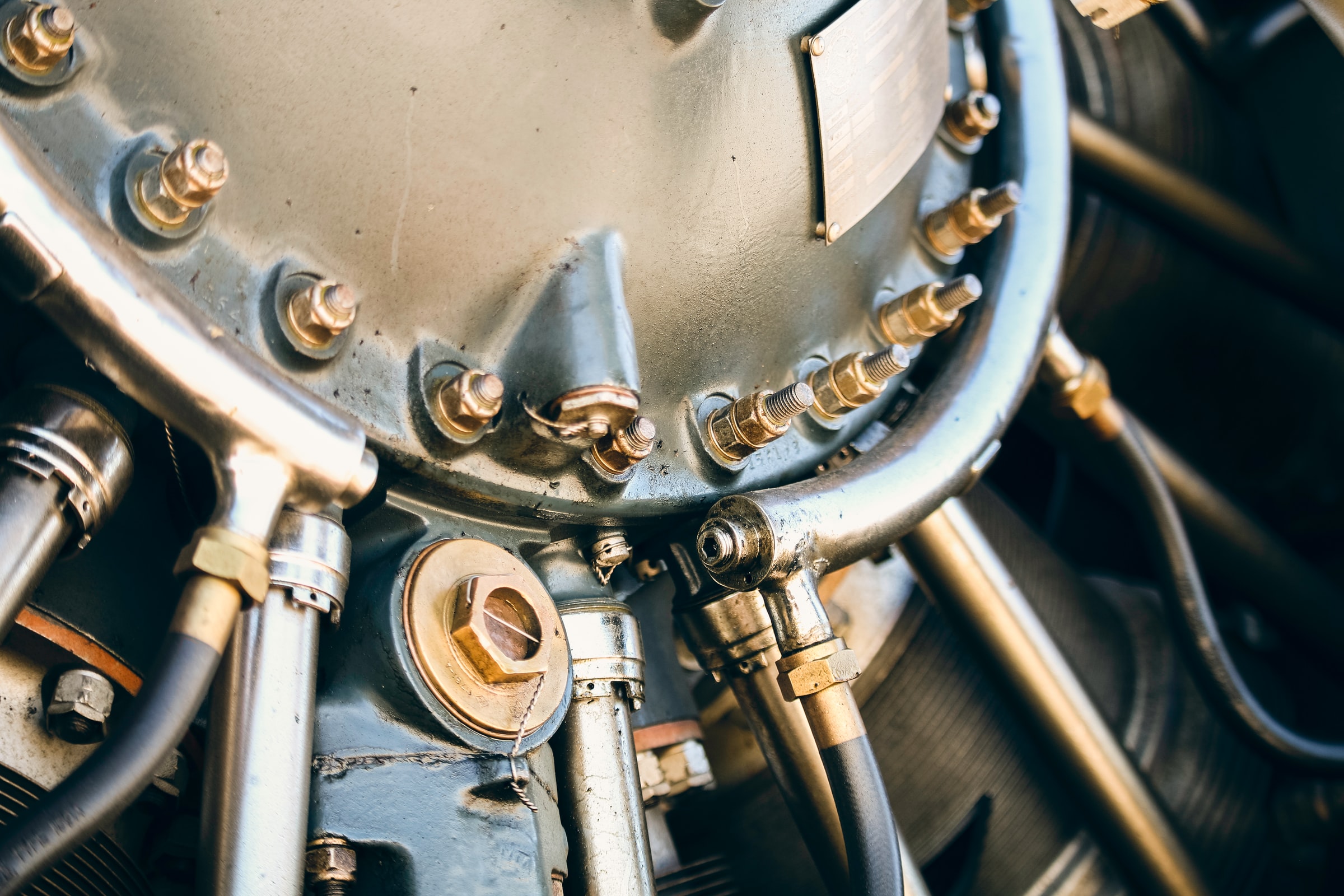

High strength and hardness polysiloxane enamel; formulated for the prevention and protection of corrosion in industrial environments and high humidity environmental conditions, as well as prolonging the useful life of structural elements or equipment.

It provides protection against hydrocarbons, cleaning chemicals and mechanical abrasion, anticipates the expansion and contraction of materials, equipment vibration and elongation. Create a layer that perfectly matches the material.

- Impact resistance; it adapts to the deformity generated in the material.

- Resistance to vibration and elongation.

- Excellent anchoring to a wide variety of substrates.

- Provides a flexible layer that anticipates the natural movements of materials.

- Corrosion extractor system; applicable on simple corrosion.

- Excellent resistance to weathering (humid and marine environments).

- Forms a waterproof film.

- High resistance to friction.

- It has a highly waterproof surface.

- High resistance to hydrocarbons, abrasive chemicals, acids, liquid condensation and extreme humidity.

- Excellent resistance to high temperatures (does not generate thermal insulation).

COMPETITIVE ADVANTAGES – Zinoxx

- APPLICABLE

- TEMPERATURE

- ENVIRONMENT

- ENDURANCE

USES AND APPLICATIONS – Zinoxx

USES AND APPLICATIONS – Zinoxx

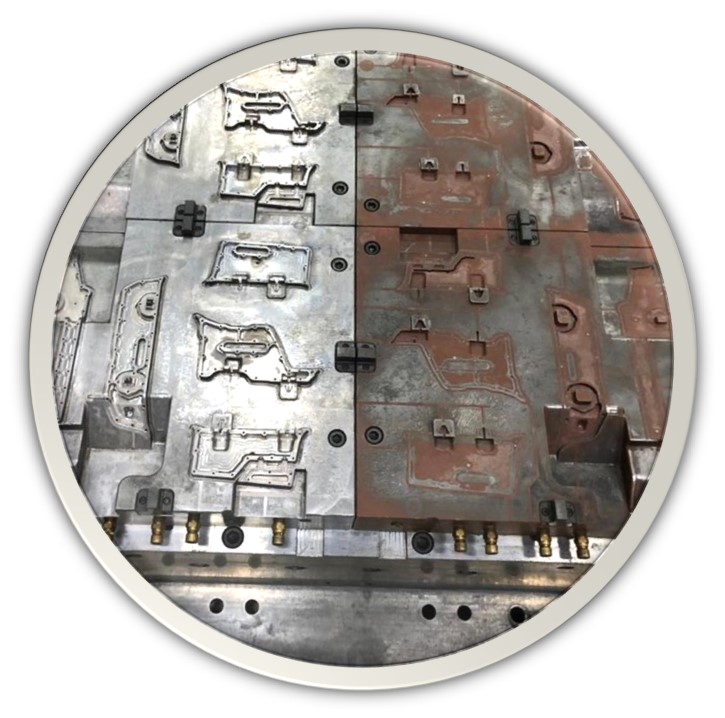

- PRIMING M

- IEHV PRIMING

- WATERPROOFING

- PRIMING I

OXI-CLEAN

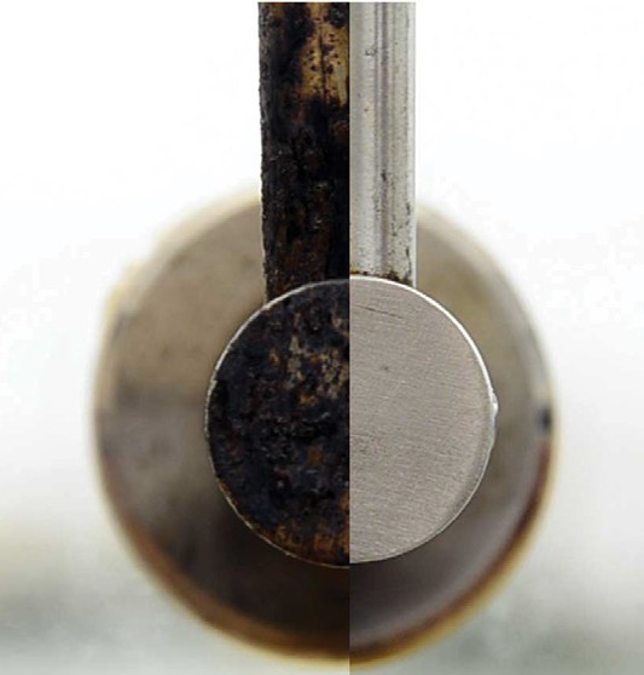

Quimic formulated of water-based organic acids focused on inhibiting corrosion by phosphating process, presents an Eco friendly base.

When applied to carbon steel, it extracts embedded saline agents, providing an invisible protective film that prevents the spread and appearance of new corrosion, for up to 5 days in coastal environments, preparing the surface for any coating or finish.

- Creates anchor profile for primers or finishes without eroding, abrading, weakening or blackening surfaces.

- Helps clean carbide precipitation in welds and oxidation in stainless steel.

- When drying, it retains its protective properties, regardless of weather conditions.

- Removes saline and corrosive agents from the roots in carbon steel.

- Anticorrosive system that penetrates the natural porosity of steel.

- Good flexibility and adaptability to metallic materials.

- Forms an invisible anticorrosive film for up to 5 days.

- Excellent degreaser for equipment or tools.

- It is not toxic or flammable.