NANOFLEX® DURA & SAPPHIRE outperform ceramic tiles

Ceramic Pro Coating: the best 9H ceramic paint protection

Looking for the best professional ceramic coating for cars “near me”? You are in the right place, we ship worldwide!

We can share more than 20 years of paint protection experience with you and provide you with customer feedback. In addition to paint on the car, wheels and headlights, the exhausts can also be protected against dirt, corrosion, bird droppings and scratches with our water repellent 9H pro nano ceramic coating, which provides performance of easy cleaning with just one layer of protection and proper maintenance.

The invisible layer of quartz and ceramic polymers will maintain the value of the coated surface at a reasonable price. DIY spray, and professional formulations available for the automotive, marine, aviation and industrial sectors, whatever floats your boat! A long-lasting protective film with superior durability and high gloss level over semi-permanent waxes or sealers (for over 50 car washes) makes polysilazane technology worth it.

In addition, we are working on superhydrophobic finishes with self-cleaning performance for paint coating, which will take professional nano-ceramic coating technology to a new level of performance in car care against water stains.

Technical data and analysis

CERAMIC PRO COATING SOLUTIONS TO MAINTAIN THE VALUE OF YOUR SURFACE:

KEY FEATURES

- Non-stick: water and dirt repellency offers long-term protection and makes cleaning easy

- Graffiti and Stain Protection – The barrier properties of ultra-dense ceramic and quartz structures protect against ingress of dirt and contamination.

- Scratch protection: surfaces are more resistant to wear

- Corrosion prevention: ultra-density stops rust at its source

- UV protection: anti-aging preserves valuable surfaces

- High temperature resistance: no change in characteristics under intense heat (up to 1000 degrees)

- The perfect finish: improved color and gloss add exceptional aesthetics to surfaces.

- Easy to apply: a perfect finish is achieved without the need for special training

APPLICATIONS OF OUR PRO CERAMIC COATING

Automotive

The use of vehicles always carries risks: damage occurs regularly. Our professional Nanoflex® Dura and Sapphire ceramic coating technology provides a remedy.

- Protection of the car body against scratches, dirt and aging

- Improved durability of decorative plastics and headlights

- Universal protection against corrosion

- Preventing brake dust from permanently adhering to wheel rims

- Our ceramic car coating can be DIY applied with a short training.

Long-term protection in the automotive sector:

Long-term protection in the automotive sector:

- Exterior: up to 100,000 km or 100 wash cycles in the car wash sector

- Interior: adapts to the durability of the surface

Aviation

- Our professional ceramic coating solution protects the aircraft fuselage from dirt and wear.

- Facilitates thawing

- Increased durability of highly stressed and decorative plastics and synthetics

- Protects surfaces from vandalism

Long-term protection in the aviation sector:

Long-term protection in the aviation sector:

- Exterior: up to 10 years

- Interior: adapts to the durability of the surface

Marine

- Our professional ceramic coating solution protects hulls from aging and corrosion and provides anti-fouling protection.

- Protection against precious metal corrosion on deck

- Delays the wear of decorative elements on the roof

- Facilitates easy cleaning of salt water residues

Long-term protection in the marine sector:

Long-term protection in the marine sector:

- Exterior: up to 10 years

- Interior: adapts to the durability of the surface

Architecture and building construction

(Exterior and interior surfaces)

Depending on their location, buildings are highly exposed to heat, regular rains, humidity, and snow. Interior surfaces are exposed to wear and dirt. Our professional ceramic tile solution can be applied in both cases.

- Reliable protection against stains on the inside of quartz, granite and marble kitchen countertops, etc.

- Visible fingerprint prevention (anti-fingerprint) on structured surfaces such as stainless steel kitchen hoods, elevators and handrails.

- Long-term protection for aluminum, synthetic or stainless steel facades from UV radiation, weathering influences and acid rain.

Long-term protection for construction and architecture with our professional ceramic cladding solutions:

Long-term protection for construction and architecture with our professional ceramic cladding solutions:

- Exterior: up to 10 years

- Interior: adapts to the durability of the surface

Industry

(machinery, construction parts, mechanical equipment)

When companies make significant investments in industrial plant and equipment, they are looking for efficient and protected long-term performance. Nanoflex® Dura and Nanoflex® Sapphire ceramic coatings provide robust protection against corrosion, calcification, wear, and dirt. show very strong chemical stability.

![]() Easy clean performance in food production (production lines, tanks, reactors)

Easy clean performance in food production (production lines, tanks, reactors)

![]() Non-stick coating for pipes, reactors used in the chemical industry, machines and utility vehicles

Non-stick coating for pipes, reactors used in the chemical industry, machines and utility vehicles

![]() Easy biofilm scrolling

Easy biofilm scrolling

TECHNOLOGY OVERVIEW

EFFECTS IN DETAIL

Easy to apply, easy to clean.

The appearance of even the best-maintained environments can easily be compromised:

![]() Sweaty hands leave permanent prints on stainless steel surfaces

Sweaty hands leave permanent prints on stainless steel surfaces

![]() Mud splashes on cars

Mud splashes on cars

![]() Los vándalos dejan graffitis en los trenes

Los vándalos dejan graffitis en los trenes

![]() Its cleaning requires a lot of time and aggressive chemicals.

Its cleaning requires a lot of time and aggressive chemicals.

The ceramic protection prepares the material for constant cleaning and contributes significantly to reducing contamination, thus saving not only time, but also in the long term reducing material costs.

How does the effect of the Ceramic Pro coating work?

Hydrophobicity is the magic word that describes the ability of Nanoflex ® Dura, Dura VF and Dura HD to repel water and keep surfaces in good condition.

Cleaning requires only a small amount of water and cleaning fluid, no abrasive or aggressive cleaning methods are necessary.

Unwanted graffiti can be removed quickly and easily. Pro ceramic coating solutions also prevent damage caused by chemicals in paints.

Easy-to-clean coatings such as Nanoflex® Dura, Nanoflex® Dura VF and Nanoflex® Dura HD are used in the following industries:

![]()

![]()

![]()

Transport:

- Automotive

- Marine

- Public transport, p. Eg trams and trains

![]()

![]()

![]()

![]()

![]()

Architecture and construction of buildings:

- Building facades

- Manufacturing plants

- Industry

- Interior accessories and accessories, e. gram. stainless steel sinks

- Our professional ceramic tile solutions can protect the following materials:

-

- Metal, e. gram. steel

- Aluminum

- Polymers (plastics)

- Glass and ceramics, p. Eg bus stops

LIGHTNING PROTECTION AGAINST WEAR AND WEAR

The slightest damage to a surface is a curse, especially on high-gloss surfaces. Our professional ceramic coating solutions for increased scratch resistance provide the automotive, construction and marine industries, and many other sectors, with optimal surface protection.

- For scratch resistant surfaces

- All it takes is a slight accidental movement when getting into a new car and the perfect surface can be damaged with a small scratch from a ring, bag or zipper.

- In addition to Nanoflex ® Dura, Dura VF and Dura HD, Nanoflex ® Sapphire provides all interior and exterior surfaces with particularly improved scratch resistance.

Use our ceramic coating solutions to obtain a scratch resistant finish on surfaces in the following areas:

![]()

![]()

![]()

Transport:

- Automotive

- Marine

- Public transport, p. Eg trams and trains

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Architecture and construction of buildings:

- Building facades

- Interior fixtures and fittings, e. g. stainless steel sinks

- Industry

- Production plants

- Our professional ceramic tile solutions can protect the following materials:

- Metal, e. gram. steel

- Aluminum

- Plastic

PROTECTION AGAINST CORROSION

![]() Weathering, high air humidity, and other harsh environmental conditions can damage materials through surface corrosion and rust.

Weathering, high air humidity, and other harsh environmental conditions can damage materials through surface corrosion and rust.

![]() Even aluminum-based materials and equipment are at risk of corrosion. Any damage to the surface will create a negative visual impact.

Even aluminum-based materials and equipment are at risk of corrosion. Any damage to the surface will create a negative visual impact.

![]() For ships, building facades, vehicles, or facilities such as wind farms and industrial facilities, corrosion can pose a big problem with regard to maintenance and safety requirements.

For ships, building facades, vehicles, or facilities such as wind farms and industrial facilities, corrosion can pose a big problem with regard to maintenance and safety requirements.

Corrosion protection not only retains the appearance of a surface, it also prevents future damage to the surface of steel and other metals. Surfaces protected by an effective ceramic coating against corrosion repel harmful elements and preserve their quality and appearance.

Our professional ceramic tile solutions are used in a large number of sectors:

![]()

![]()

![]()

![]()

Transport:

- Industry automotive

- Marine

- Aviation

- Public transportation, e. gram. trains and trams

![]()

![]()

![]()

![]()

![]()

![]()

Architecture and building construction

- Building facades

- Decorative interior accessories, e. gram. stainless steel sinks

- Industry

- Wind farms

- Production plants

- Pipelines

CERAMIC COATING FORMULAS PRO IN DETAIL

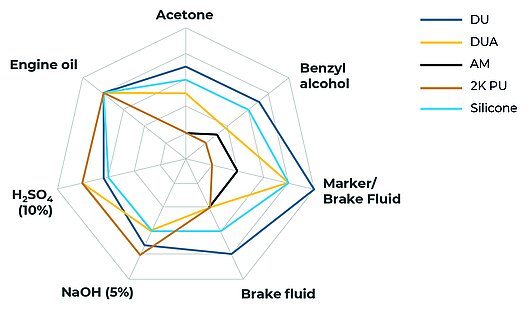

DURA CHEMICAL RESISTANCE

5: No effect – no detectable change in the surface of the material.

4: Excellent – Slight detectable change in color or gloss, but no change in surface function or life.

3: Good – A clearly noticeable change in color or gloss, but no significant deterioration in surface life or function.

2: Fair – Significant change in appearance due to fading or etching, possibly resulting in impaired function over an extended period of time.

1: Fault: pits, craters or surface erosion. Obvious and significant deterioration.

DU: Dura derivatives

DUA: Hard as a lacquer additive

AM: Alkyd Melamine System

PU: 2K polyurethane system

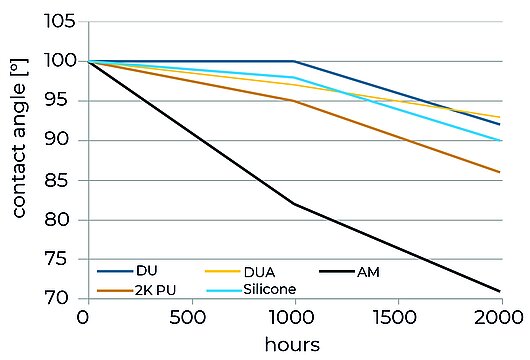

WEATHER RESISTANCE by DURA

- Paints and varnishes DIN EN ISO 11341

- Artificial aging and exposure to artificial radiation.

- Exposure to filtered xenon arc radiation (2000 hours)

DU: Dura derivatives

DUA: Hard as a lacquer additive

AM: Alkyd Melamine System

PU: 2K polyurethane system

APPLICATION

PRODUCT APPLICATION AND TOOLS

All versions of our professional ceramic tile products are supplied ready to use. Depending on the substrate, they can be applied with microfiber applicators or paint rollers (microfiber flocking). The product is also suitable for spray application.

Spray application

Process: HVLP compressed air

Working pressure: approx. 2 3 bars

Nozzles: 0.8-1.3mm

The spray gun can be cleaned with, for example, butyl acetate

Shelf life: 12 months from the date of delivery, at 20 C

SUBSTRATE STATE

The substrate to be coated must be clean, free of grease and completely dry. Areas of difficult access, such as cavities or drainage channels, etc. should be dried with absorbent cloths or dried with compressed air. In contact with a wet substrate surface, ceramic tiles react prematurely and cannot form a permanent bond. The substrate and the ambient temperature must be between + 5 ° C and + 30 ° C, the relative humidity between 30% – 80%.

Dura, Dura VF and Dura HD – Full cure at room temperature in 5-7 days

The recommended curing conditions for our professional ceramic coating solution (until waterproof) are:

- Room temperature 8-12 hours

- 80 ° C two hours

- 130 ° C – 180 ° C one hour

Sapphire and Sapphire Base Coat – Full cure at room temperature in 24 hours

Recommended curing conditions (until waterproof) are:

- Room temperature 6 hours

- 80 ° C 1 hour

- 130 ° C – 180 ° C: 30 minutes

SEGURIDAD Y ALMACENAMIENTO

![]() SAFETY

SAFETY

Las instrucciones de seguridad para nuestras soluciones de revestimiento cerámico profesional se detallan en la hoja de datos de seguridad del material y deben seguirse incondicionalmente.

- Wear solvent resistant gloves (eg butyl or nitrile rubber gloves) when applying product.

- Wear suitable eye protection (safety glasses or mask).

- Provide adequate ventilation of the work area.

- The use of a half mask with type A2 B2 E2 K2 Hg / P3 filters is recommended when applying the product.

- The solution must not be mixed or diluted with other solvents.

- Store in a cool (10 C) dry place with adequate ventilation.

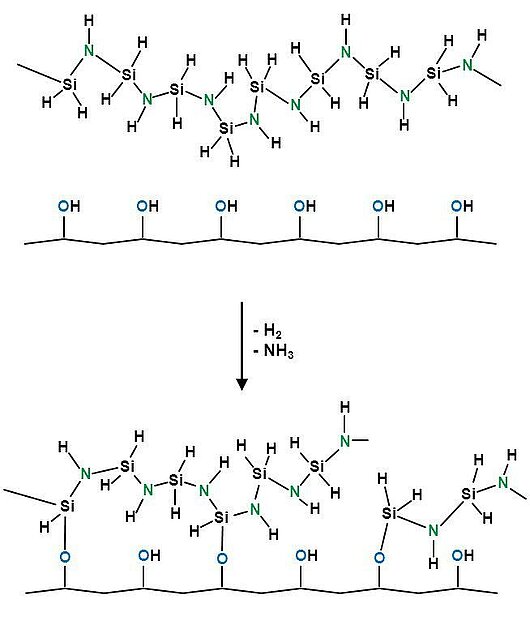

- Open the container periodically to release overpressure (ammonia, hydrogen).

- Keep away from fire, sparks, water, humidity, alcohols and other chemical substances.

![]() STORAGE

STORAGE

Pro ceramic tiles should be stored in a cool and dry place at 10 C), with sufficient ventilation Ventilate sealed containers regularly (once a month) to release pressure Ventilation dates should be verifiable This activity will minimize ammonia build-up, hydrogen and self-igniting silane gas

Avoid scams and fraud! – characteristics of pro 9H ceramic tiles

- Ammonium hydroxide odor Polysilazanes can only be made using it

- Moisture sensitivities react with moisture in the air to create a chemical bond.

- Sold in pressure resistant glass or aluminum bottles that can withstand pressure in the bottle

- No odor of ethanol solvent! this is from silane or polysiloxane technology with only a fraction of durability and protection